While you might think cable ladder racks are just basic infrastructure, they’re actually critical to protecting your network investment and maintaining operational efficiency. You’ll find that selecting the right rack system impacts everything from installation time to future scalability and compliance requirements. As the year 2025’s options showcase significant improvements in design and materials, you’ll want to understand which features truly matter for your specific needs – before making this essential purchase.

ICC Cable Runway Ladder Rack Wall Mount Kit

For IT professionals seeking a robust American-made cable management solution, the ICC Cable Runway Ladder Rack Wall Mount Kit delivers industrial-strength performance with its 16-gauge cold-rolled steel construction and 500-pound load capacity.

You’ll appreciate the complete mounting package, which includes a 5-foot runway section, brackets, protective end caps, and hardware. The black powder-coated finish adds durability while TIA compliance guarantees industry standards. Integration is seamless with ICC’s broader ecosystem of runway sections and corners, making future expansion straightforward. With a 4.2-star rating and positive feedback on sturdiness, this wall mount kit proves its worth in professional data center environments.

Best For: IT professionals and data center managers who need a heavy-duty, wall-mounted cable management solution that offers professional-grade construction and easy integration with existing infrastructure.

Pros:

- Made in USA with industrial-grade 16-gauge steel construction and 500lb load capacity

- Complete mounting kit includes all major components and hardware needed for installation

- TIA-compliant with seamless integration capabilities for future expansion

Cons:

- Some reports of missing minor installation hardware

- Higher price point compared to basic cable management solutions

- 5-foot fixed length may require cutting for custom installations

VEVOR Extendable Truck Ladder Rack (800 lbs Capacity)

Truck owners seeking a versatile and robust ladder rack will appreciate the VEVOR Extendable Truck Ladder Rack‘s impressive 800-pound capacity and adjustable width range of 49-73 inches. This black steel rack features rope hooks for securing kayaks, surfboards, and lumber while resisting harsh weather conditions through its anti-corrosion coating.

While installation requires drilling into bed rails and isn’t compatible with tonneau covers, users praise its sturdy construction and value. The 38.6-pound rack’s design includes two T tube rods and a central crossbar, though some reviewers note concerns about paint quality and suggest upgrading to stainless steel bolts for better durability.

Best For: Truck owners who need a heavy-duty, adjustable rack for transporting ladders, lumber, kayaks, and other large items while maintaining flexibility to fit different truck bed sizes.

Pros:

- High load capacity of 800 pounds with durable steel construction

- Adjustable width (49-73 inches) accommodates various truck bed sizes

- Includes rope hooks and weather-resistant coating for versatile, all-season use

Cons:

- Installation requires drilling into bed rails

- Not compatible with tonneau covers or bed track systems

- Some quality concerns with paint finish and standard bolts prone to rusting

Kable Kontrol Wire Mesh Cable Tray (5 Feet, 8″ Width)

Network administrators and IT professionals seeking reliable cable management will find their match in the Kable Kontrol Wire Mesh Cable Tray. At 5 feet long and 8 inches wide, this zinc-plated steel tray offers ample space for organizing network cables, fiber optics, and AV systems.

You’ll appreciate the chrome finish and electro-zinc resistance that guarantees lasting durability. The NEC-approved design allows for custom sizing to fit your specific needs. While the tray’s versatility extends to garage shelving applications, be aware you might need to purchase additional mounting hardware separately, as some customers note missing components in their packages.

Best For: IT professionals, network administrators, and facility managers looking for a durable, customizable solution for organizing cables in commercial or industrial settings.

Pros:

- Sturdy zinc-plated steel construction with chrome finish for long-lasting durability

- Customizable sizing options to fit various installation needs

- Versatile applications from network cabling to garage storage solutions

Cons:

- Required mounting hardware often not included in package

- Additional components may need to be purchased separately

- Some customers report installation challenges requiring extra hardware store visits

ICC Cable Runway Rack Straight Section with End Splice Kit (2-Pack)

Data center managers seeking reliable cable management will appreciate the ICC Cable Runway Rack’s robust design and scalability. Made in the USA from 16-gauge cold-rolled steel, this two-pack system creates a continuous 10-foot run that’s both TIA-compliant and Section 889 certified.

You’ll find the rack’s 500 lb load capacity at 50% fill perfect for bulk cable management while maintaining essential airflow. Its 12-inch-wide pathway accommodates your growing infrastructure needs, and the lightweight tubular design makes installation straightforward. The black powder-coated finish and included butt splice kit guarantee durability and seamless integration with other ICC components for future expansion.

Best For: Data center managers and IT professionals who need a robust, scalable cable management solution that meets industry compliance standards while supporting heavy cable loads.

Pros:

- Made in USA from high-quality 16-gauge steel with 500 lb load capacity

- TIA and Section 889 compliant with professional-grade construction

- Easy integration with existing ICC components for future expansion

Cons:

- Limited to 12-inch width which may not suit all installation needs

- Requires purchase of additional components for complete system setup

- Two-pack configuration may be more than needed for smaller installations

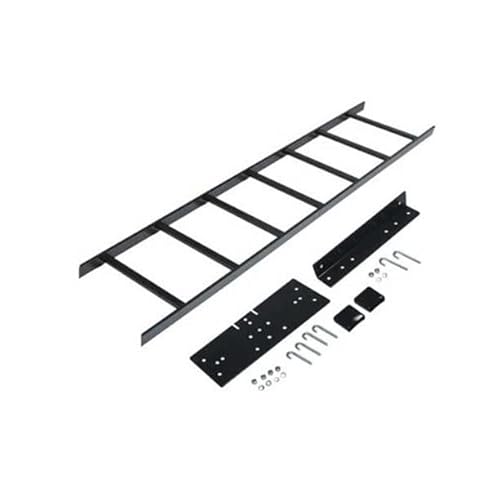

WAV-WL-R1205-KIT 5 Rack-to-wall-kit Ladder Rack

When you need reliable overhead cable management, the WAV-WL-R1205-KIT ladder rack delivers professional-grade performance with its black powder-coated steel construction. The 5-foot rack provides lasting strength and stability while ensuring even cable distribution across your workspace.

You’ll appreciate its versatile design, compatible with common cable management systems and all distribution racks. Installation is straightforward with the U-bolt mounting system, and at 18 pounds, it’s substantial enough for demanding setups. The rack’s 61-inch length offers ample space for horizontal cable routing, making it an efficient solution for organizing your cable infrastructure.

Best For: IT professionals and facilities managers seeking a robust overhead cable management solution for server rooms, data centers, or studio environments.

Pros:

- Durable black powder-coated steel construction ensures longevity

- Universal compatibility with common cable management systems and distribution racks

- Easy installation with U-bolt mounting system

Cons:

- Relatively high price point for a cable management solution

- Limited customer reviews available to assess long-term reliability

- Substantial weight of 18 lbs may require additional installation support

AA-Racks Non-Drilling Steel Pickup Truck Ladder Rack Two-Bar Set

For pickup truck owners seeking a sturdy, no-drill solution, the AA-Racks Steel Ladder Rack Two-Bar Set delivers impressive versatility with its 800-pound load capacity. The powder-coated matte black rack features an extendable design that fits truck beds from 51 to 71 inches wide.

You’ll appreciate the hassle-free installation using eight included aluminum C-clamps, though you can’t use this rack with bed covers or camper shells. With a 30.5-inch clearance height, you’ll easily transport kayaks, lumber, and other lengthy materials. While some users report occasional clamp loosening, the robust construction and easy setup make this rack a reliable choice for your hauling needs.

Best For: Pickup truck owners who need a versatile, drill-free cargo rack solution for hauling ladders, lumber, kayaks, and other long materials while maintaining full bed access.

Pros:

- High load capacity of 800 lbs with sturdy steel construction

- No-drill installation with included aluminum C-clamps

- Adjustable width fits multiple truck bed sizes (51-71 inches)

Cons:

- Not compatible with bed covers or camper shells

- Some users report clamps may loosen over time

- Potential for rust issues around installation points

StarTech.com 1U Rack Mountable Cable Lacing Bar with Adjustable Depth

IT professionals seeking premium cable management will appreciate the StarTech.com 1U Rack Mountable Cable Lacing Bar‘s versatility and durability. Made from heavy-duty 5/64-inch SPCC steel with a powder-coated finish, this 19-inch bar fits standard server racks while offering adjustable depth from 1.5 to 3.7 inches.

You’ll find installation straightforward with included M6 cage nuts and screws. The bar features 0.3-inch spaced lacing points and dual-mode mounting options for superior cable routing. It’s compatible with various equipment, from patch panels to PDUs, and comes with a two-year warranty plus lifetime technical support.

Best For: IT professionals and data center managers who need robust cable management solutions in standard 19-inch server racks and require adjustable depth options for optimal cable routing.

Pros:

- Heavy-duty steel construction with powder coating ensures long-term durability

- Adjustable depth mounting (1.5″ to 3.7″) provides installation flexibility

- Includes all necessary mounting hardware and comes with comprehensive technical support

Cons:

- Relatively high price point compared to basic cable management solutions

- Additional cable management accessories must be purchased separately

- May require minor adjustments for perfect fit in some rack configurations

Factors to Consider When Choosing a Cable Ladder Rack

Before selecting a cable ladder rack, you’ll need to evaluate essential factors including your specific load capacity needs and the available mounting options for your space. You should carefully consider the installation method types that work best for your environment, along with the durability of materials like steel or aluminum that can withstand your facility’s conditions. The size and space requirements of your cable management system will ultimately determine which rack solution fits your infrastructure while allowing for future expansion.

Load Capacity Requirements

Understanding load capacity requirements stands as one of the most critical factors when selecting a cable ladder rack. You’ll need to ascertain your chosen rack can handle loads between 500 to 800 lbs, depending on your installation needs.

When planning your cable management system, you’ll want to assess weight distribution carefully. It’s best to maintain a 50% fill rate for peak performance and safety. The material choice notably impacts load capacity – 16-gauge steel offers superior support compared to lighter options.

You should evaluate whether your setup requires a single or double section run based on your expected maximum load. Don’t forget to verify that your selected rack meets industry standards and regulations. This verification isn’t just about compliance – it’s crucial for maintaining a safe and reliable cable management system.

Installation Method Types

When selecting a cable ladder rack, you’ll encounter several installation methods that can make or break your setup’s success. You’ll need to choose between drilling and non-drilling systems, with the latter offering quicker assembly for temporary or adjustable setups.

Wall-mounted options require secure bracket installation using bolts or screws, ensuring your rack can handle its intended load capacity. If you’re looking for flexibility, consider adjustable systems that let you modify dimensions and configurations to match your space requirements. Lightweight designs are particularly useful when you’re working alone or in tight spaces, as they’re easier to position and align.

Your choice of installation method directly impacts both load capacity and cable management efficiency, so prioritize systems that offer secure mounting while meeting your specific needs.

Material and Durability

The material and construction quality of your cable ladder rack serve as the foundation for its long-term performance. When selecting a rack, you’ll want to focus on options made from 16-gauge cold-rolled steel, which offers superior strength and resistance to bending under heavy loads.

Look for racks with black powder-coated finishes, as they’ll provide enhanced protection against corrosion and environmental damage. You’ll need to match your material choice to your load requirements – quality racks can support up to 500 lbs at 50% fill capacity. Additionally, verify your chosen material allows proper airflow while minimizing cable strain. Remember that TIA-compliant materials aren’t just a bonus feature – they’re essential for meeting industry safety standards in both commercial and residential installations.

Size and Space Needs

Proper sizing of your cable ladder rack begins with a thorough assessment of your available installation space. You’ll need to account for both current requirements and future expansion possibilities, as many racks exceed 5 feet in length. When measuring, consider the width requirements – standard trays range from 2 to 12 inches wide, which directly impacts your cable organization options.

Don’t forget to evaluate the vertical clearance needed for your installation, as height variations can affect mounting options. Load capacity is equally essential – you’ll want to choose a rack that can support between 500 to 800 pounds, depending on your cable volume. If you’re planning to scale up later, select a model that’s compatible with additional sections and mounting hardware to save yourself future headaches and reinstallation costs.

Mounting Options Available

Several mounting options exist for cable ladder racks, each designed to meet specific installation requirements. You’ll find wall-mounted setups and rack-to-wall kits that let you run cables horizontally across different heights with ease. The inclusion of U-bolts and J-bolts makes installation straightforward and secure, eliminating complex procedures.

When selecting your mounting option, you’ll appreciate that most racks are compatible with standard mounting hardware, making them highly adaptable to your existing infrastructure. If you’re looking for a non-invasive solution, consider racks with clamp-based installations that don’t require drilling. For maximum flexibility, opt for adjustable mounting designs that can align with various rack sizes and heights, ensuring your cable management system works efficiently regardless of your setup requirements.

Environmental Exposure Conditions

Beyond mounting considerations, environmental conditions play a major role in determining the right cable ladder rack for your installation. You’ll need to select materials that can withstand your specific location’s challenges. If you’re installing in coastal areas, choose racks with anti-corrosion coatings to combat saline air exposure. For outdoor installations, galvanized steel offers excellent protection against moisture and harsh weather.

Consider adding powder-coated finishes for extra durability in high-humidity environments. When evaluating options, look for racks rated to support at least 500 lbs at 50% fill to guarantee they’ll handle both cable loads and environmental stresses. Don’t forget to factor in your area’s typical weather patterns, including wind and rain intensity, as these will affect your rack’s required stability and load-bearing capabilities.

Expandability and Integration

When planning your cable ladder rack installation, prioritize systems that offer seamless integration and expansion capabilities. You’ll want to select racks that can easily connect with your existing cable management infrastructure while accommodating future growth.

Look for racks that provide flexible modification options, including the ability to cut sections to custom lengths and add new components as needed. Your chosen system should support various mounting hardware and runway sections, making it adaptable to changing requirements. It’s critical to choose a rack with substantial load capacity—aim for at least 500 lbs at 50% fill—to maintain structural integrity during expansions. Don’t forget to verify TIA compliance, ensuring your system will remain compatible with emerging technologies and industry standards as your network infrastructure evolves.

Cost Vs Quality Balance

Balancing cost against quality presents an essential decision point in selecting the right cable ladder rack for your infrastructure needs. While budget-friendly options might seem attractive initially, they can lead to unexpected expenses through missing hardware or compatibility issues with your existing setup.

You’ll want to examine products with ratings between 4.2 and 4.5 stars, as these typically offer the sweet spot between price and performance. Look for racks that support at least 800 lbs at 50% fill capacity, even if they cost more upfront. Additionally, you shouldn’t overlook compliance certifications like TIA and Section 889 – they’re reliable indicators of quality and safety standards. Remember, investing in a higher-quality ladder rack often pays off through superior durability, better load capacity, and seamless system integration.